Six Sigma Yellow Belt Certification

A Yellow Belt participates as a core team member or subject matter expert (SME) on a project or projects. In addition, Yellow Belts may often be responsible for running smaller process improvement projects using the PDCA (Plan, Do, Check, Act) methodology. PDCA, often referred to as the Deming Wheel, which enables Yellow Belts to identify processes that could benefit from improvement. These smaller Yellow Belt projects often get escalated to the Green Belt or Black Belt level, where a DMAIC methodology is used to maximize cost savings utilizing Statistical Process Control.

About Course

Duration

Trainer Profile

Ratan Pandey

- He is a certified black belt & master black belt from International General Electric &

ASQ having more than 20 years in utilizing Six Sigma Concept, tools & methodology to

influence business results.

He has been leading business transformation projects in manufacturing, service & health

sectors. Trained hundreds of professionals in manufacturing /service sectors & completed

more them 150+ black belt projects with core expertise in warranty reduction Lean,

business modeling &design of experiment

Ratan is B.E. (Mechanical) from SU, M. Tech (Operation) from NIT Jamshedpur & DBA-

Material Management from (IMT), is having 25 years of experience in working with leading

Indian & global manufacturing & service company

Practice Area—Business Process Improvements, Design Thinking, Innovation, IoT & Data

Science

Deepak Sethi

- He is a certified Six Sigma Black Belt from ISLIQF, Certified Lean Professional, Lead

Auditor, Trained on Program Management Skills.

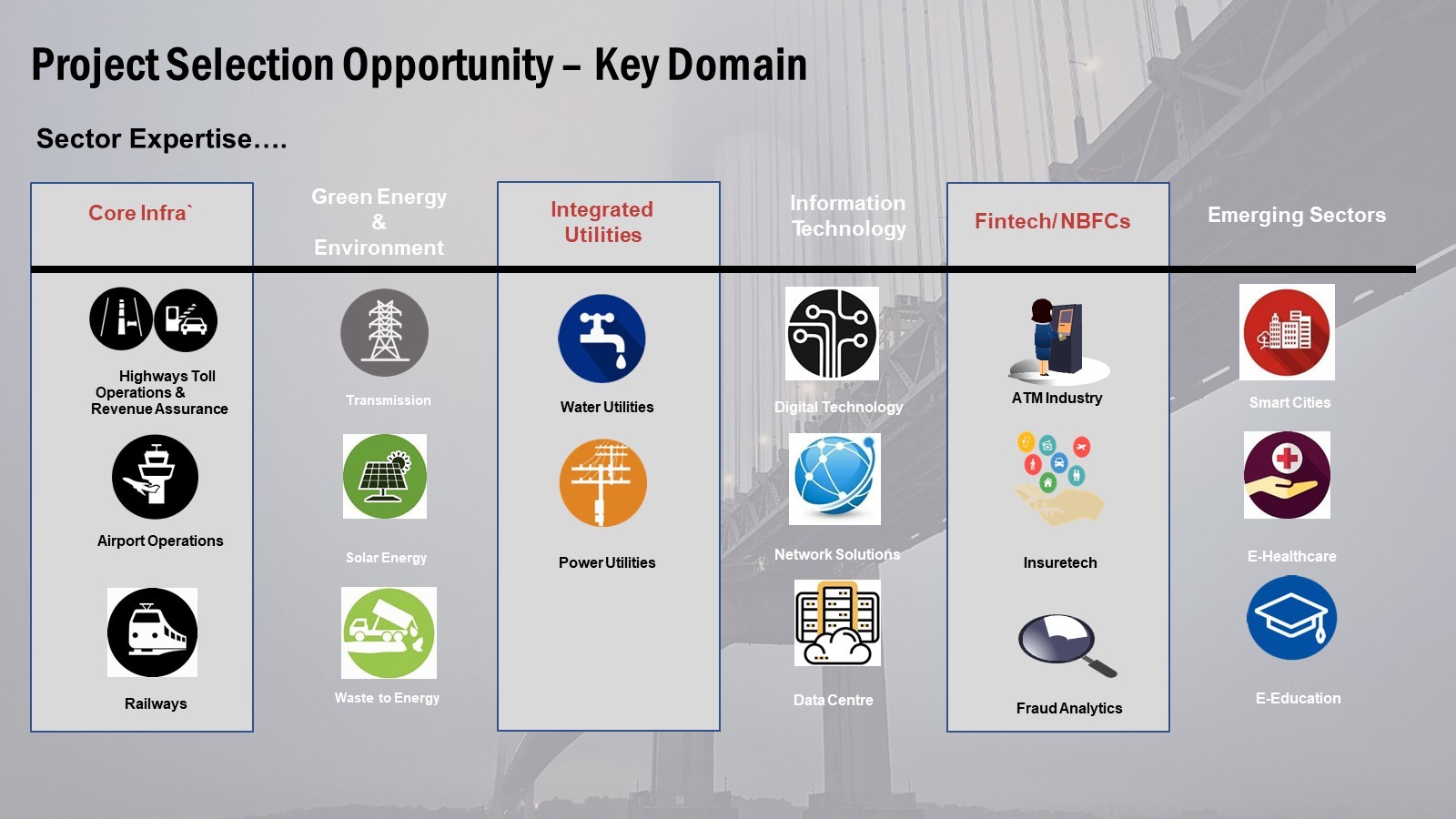

He is an SME for Automobile, Telecom, Infrastructure Highway Construction, Solar, City

Water distribution & Treatment, Power Distribution, Health Care NABH, NABL consulting,

with more than 25 years experience across Manufacturing & Service Sectors.

On academic front he is BE Mechanical.

Deepak has been leading business transformation projects in manufacturing, service &

health sectors. Trained 2000+ of professionals in manufacturing /service sectors &

completed more than 100 Green & Black belt projects.

Practice Area—Business Process Re-engineering, Industry 4.0 concept to execution and

Lean Principles

Learning Benefits

- Cultivate capabilities in Fact-Based decision making & Data-Driven problem solving

- Gain the skill to explore + analyze + solve management problems using different Management Tools

- Sharpen your Business Acumen & commitment to improving processes within your organisation

- Derive useful Information from Data using analytical tools

- Learn essential Project Management + Leadership skills

- Gain the skill to make Customer-Centric Actions at every stage

- Understand the science to develop high-quality products/services

- Develop the capability to look beyond the present field with this domain and industry independent methodology

Career Benefits Designation

- Become Eligible for jobs demanding analytical background

- Fill the void of thousands of untapped High-Paying Jobs for Six Sigma Certification Holders having Talent Shortage

- Open doors to Job Opportunities Abroad demanding specialization

- Improve your CV & Linkedin Profile with professional development

- Distinguish your profile from peers during Job Interviews

- Support a Startup with improved Process and Performance that leads to high-quality products and services

Course Curriculum – Objective-Based Curriculum Plan

- Objective : Understanding Lean & Six Sigma, 7 types of Waste, understanding 'Customer' & its Voice, Defining CTQ, Learning Value-Added & Non-Value Added activities

- Objective : Project-Charter Preparation, Un-abbreviating SIPOC, Understanding of different applied Datatypes & their Validation

- Objective : Basic Statistics, 7 Quality tools (Process Mapping), Subjective tools (Root-cause Analysis & Matrix), Visualization techniques (Histogram, Box Plot, Pareto, Scatter plot & Trend analysis), understanding 'Why –Why' & Control Impact Analyses

- Objective : Generation & section of ideas, Mistake proofing, implementing the counter measures, Control plan & CTQ Performance.5. Upcoming Batches - Date And Price with 'Enroll Now' Option